Gravure Coating Machine

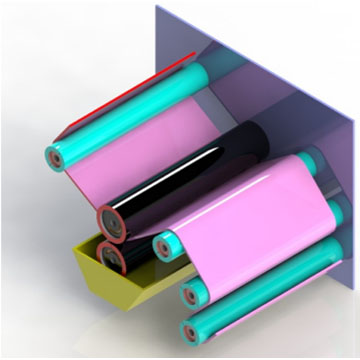

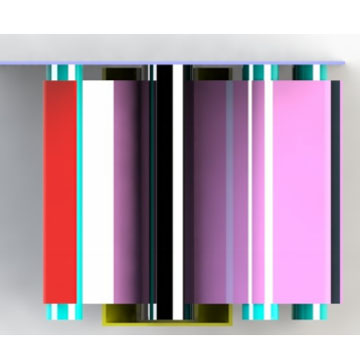

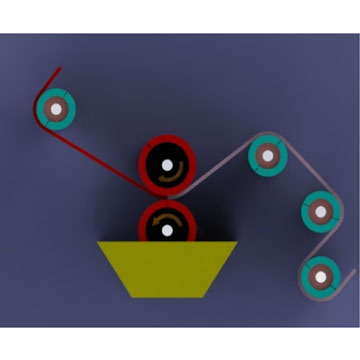

The gravure coating process depends on an engraved roller running in a coating shower, which fills the engraved specks or lines of the roller with the coating material. The overabundance coating on the roller is wiped off by the Doctor Blade and the coating is then saved onto the substrate as it goes between the Engraved roller and a Pressure Roller

The Gravure Coater has turned into a standout amongst the most famous sorts of coaters being used today because of its capacity to apply less coating with more exactness than different strategies. Gravure coating is an adaptable coating process that can apply a coating slender coating, 3-65 microns wet scope, from a low consistency arrangement, 30-2000 cp,at accelerates to 2300 fpm. The essential idea of the process is generally basic. A designed roller from a coating dish grabs the coating fluid, the abundance is doctored off and the fluid exchanged from the filled cells to the substrate. There are three sorts of Gravure coaters: direct gravure, reverse gravure, and differential offset gravure.

Related images