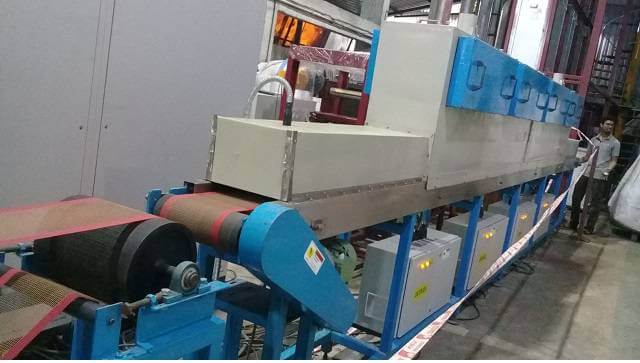

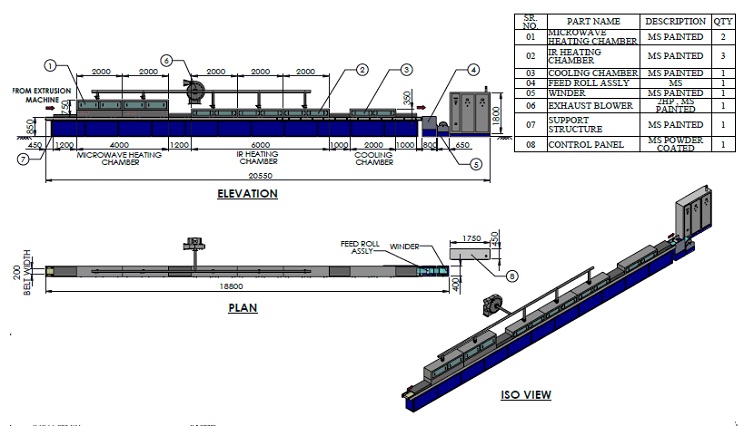

Microwave and Infrared Rubber Vulcanization Line

Vulcanization is the way of transforming natural rubber and comparable versatile polymers into durable products by cross-connecting the polymer molecules, for example building extra extensions/bridges between them through the expansion of sulfur or other identical "curatives." Uncured natural rubber is sticky, twists effectively when warm, and is easily breakable when cold and thus is exceptionally poor in elasticity. Vulcanized materials are less sticky and have exceptional mechanical properties. The procedure is named after Vulcan, the Roman God of Fire. A huge range of items are made with vulcanized rubber including tires, sealings, shoe soles, hoses and so on.

This process of rubber vulcanization can be done by the accompanying 2 heating systems:

1.Infrared Heating System

2.Microwave Heating system

Infrared Heating System in Rubber Curing: Infrared Rubber curing frameworks is exceedingly proficient for the pre-vulcanization of profiles and hoses. Arranged between the rubber extruder and the consistent vulcanization line, the powerful infrared radiation pre-fixes the outside of the rubber items. This is identified with a superior dimensional dependability and an amazing surface quality. Regularly these frameworks are around one meter long and have a warming limit of around 30 kW. In any case, elastic is a poor conductor for warm vitality and henceforth there was an appeal of microwave heating systems.

Microwave Heating system in Rubber Curing: Rubber vulcanization has been a tremendously mainstream utilization of Microwave Heating. While there are additionally kinds of cold vulcanization, microwave frameworks are constantly utilized for hot vulcanization. The constant vulcanization of elastic profiles is the fundamental utilization of microwave vulcanization frameworks. As the warmth move in other warming frameworks just happens through the outside of the item, the warming procedure is tedious and can prompt negative impacts like over-restoring and so forth. So as to abbreviate down the vulcanization time and to maintain a strategic distance from conceivable issues, these parts can be pre-warmed utilizing microwaves, as the radiation enters the elastic and warmth the material from center to surface all the while and subsequently microwave relieving is quick.

Application Industries:

Salient Features of the Rubber Vulcanization Lines:

KERONE Engineering Solutions Ltd. is a pioneer in application and executing designing arrangements with its tremendous experience and group of experts. Since most recent 42 years, it has been into planning, fabricating and introducing of Industrial apparatus for different preparing needs. The architects and experts at KERONE have inside out knowledge of various heating technologies and give solutions applying them in an immense no. of Industrial machines.

Related images