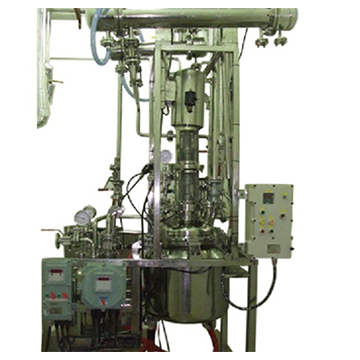

Skid Mounted Reaction Unit

Necessity of Skid Mounted Reaction Units

Expensive and high-grade products are not produced in large quantities, as they are typical for pharmaceutical industry, & also forfine/special chemical areas.

Small, flexible facilities are necessary for these applications, which can be easily cleaned quickly be adjusted for the next product.

They need corrosion resistant materials that do not interact with the product and do not contaminate it.

In addition, it is frequent that only limited space is available for the assembly of the facility, and therefore compact design is preferred.

Solution

Traditionally, the fine chemical and pharmaceutical industries have favoured batch reaction, so we have provided multipurpose reactors which can perform various chemical reactions.

KERONE has developed a systems perspective to reaction technology, whereby a fully functional reaction unit, including peripheral equipment, is built and assembled in our workshop as a skid, then delivered to the customer as a complete operational system.

Features

- Reactor of respective size with Mechanical seal, suitable agitator, Motor, Gear Box, Bottom valve & Cladded insulation.

- Main Condenser & Vent condenser with distillate cooler & vapour column from reactor.

- Liquid reactant addition vessel of suitable size.

- Two distillate receivers of suitable size.

- Distillate & reflux lines within skid.

Reactions / Operations

- Any type of reactions involving Liquid – Liquid, Liquid-Solid, Liquid–Gas reactions.

- Any operation like continuous addition of liquid reactant, mixing of the two phase liquids, layer separation etc.

- Any distillation operation involving reflux, moisture separation (Dean Stark), high vacuum distillation etc.

- Any reaction involving highly viscous material, OR crystallization operation.

- Any customer specific requirement could be discussed at the design stage.

Plug & Play Feature

- All the process piping is complete within the skid & requires external connections only.

- Vacuum pump connection to the reactor system needs to be connected at one place only. Distribution of the vacuum within skid is already provided.

- All the cabling within the skid is provided. The customer needs to connect only power connection to the system.

- Condenser utility supply manifold is provided within the skid.

cGMP compliant Features

- All the wetted & non wetted parts are of Suitable grade stainless steel.

- All the surfaces are polished to avoid any deposition of the reaction mass on the surface & improve the cleanability of the same.

- All the gaskets used in the system are of PTFE which are very easy to clean. These gaskets are also compatible over wide range of

- temperature & pressure in almost every solvent.

- All the piping & condensers are designed in such a way that there is no any liquid hold up in the system at the end of the batch.

- After every batch the reactor base could be removed very easily & can be cleaned so as to ensure no contamination from previous batch.

- Mechanical seal area of the top dish could be flushed thoroughly from the bottom side. Lantern stool of the agitator could be lifted easily without dismantling any nozzle of the reactor for cleaning purpose.

- We can provide CIP system to flush all nozzles of the reactor using suitable solvents.

- We carry out validation of the system in cGMP point of view & submit all the relevant documents along with the system.

Instrumentation Provided

Product Range

Related Products